Choosing the Right Concrete Drilling Method: Core Drilling vs. Percussion Drilling

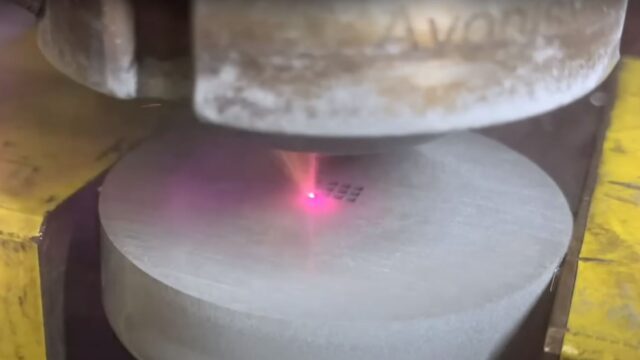

Understanding Core Drilling

Core drilling is a precise method, primarily utilised to create circular holes in concrete structures. It employs a diamond bit to extract a cylinder of material, often referred to as the ‘core’. With core drilling, you get:

- A smooth finish

- Consistent hole diameter

- Ability to drill at various angles

- Precision in avoiding reinforcements or post-tension cables

Insight into Percussion Drilling

Percussion or ‘hammer’ drilling, on the other hand, relies on a pulsating mechanism to break up the material and extract it. This method is characterised by:

- Rapid drilling speeds

- Suitability for smaller holes

- Higher noise levels

- Not as precise as core drilling

Factors to Consider When Choosing a Drilling Method

Selecting the right technique depends on the specifics of your project:

- Purpose of the Hole: If you need to install electrical or plumbing systems, core drilling provides cleaner, larger holes that cater to such requirements.

- Depth and Diameter: Core drilling is perfect for deep holes with consistent diameter. In contrast, percussion drilling is more suited for shallow, smaller-diameter holes.

- Material Type: While both methods work on concrete, core drilling’s precision is more suitable for denser, reinforced concrete.

- Noise Concerns: In residential areas, like Greenlane and Grey Lynn, where noise can be a concern, core drilling might be more neighbour-friendly due to its quieter operation.

Auckland Council Bylaw Considerations

Concrete drilling isn’t just about choosing a method. Auckland’s regulations play a significant role in decision-making. For instance:

- Certain suburbs, due to their historical or environmental significance, might have restrictions on noise levels and construction times. Greenlane and Grey Lynn fall under such zones.

- The Auckland Unitary Plan dictates guidelines on noise and vibration levels. If your project is near sensitive areas (schools, hospitals), adhering to these guidelines becomes crucial.

- Always check with the regional councils for specific codes and permissions before commencing your project. It’s not just about compliance; it’s about being a good neighbour.

Environmental and Safety Factors

Safety should never be compromised:

- Dust Control: Core drilling, being a wet process, helps in suppressing dust. Conversely, percussion drilling, if done dry, can release significant amounts of dust, necessitating protective measures.

- Noise: As mentioned, percussion drilling is louder, which might necessitate ear protection.

- Structural Integrity: Drilling without proper assessment can weaken the structure. Always consult with an expert before making large holes in load-bearing walls.

Cost Implications

Your budget also influences your choice:

- Equipment Rental: Core drilling equipment, being more specialised, might be costlier to rent than standard percussion drills.

- Labour Costs: The precision of core drilling might mean a longer project timeline and potentially higher labour costs.

- Cleanup: The wet process of core drilling might require additional cleanup, factoring into the overall project cost.

Final Thought

Both core and percussion drilling have their merits. While core drilling offers precision, percussion drilling might be faster for smaller tasks. Always factor in the nature of your project, council bylaws, and safety considerations. And remember, consulting with local Auckland construction experts will ensure your renovation is both efficient and compliant.

Frequently Asked Questions about Concrete Drilling in Auckland

What is core drilling?

Core drilling is a technique used to create circular holes in concrete structures. It employs a diamond bit to extract a cylindrical section of material, known as the ‘core’.

How does percussion drilling work?

Percussion or ‘hammer’ drilling relies on a pulsating mechanism to break up the material, making it ideal for creating smaller holes quickly.

Which method offers more precision?

Core drilling offers greater precision, ensuring consistent hole diameter, and the ability to avoid reinforcements or post-tension cables in the concrete.

Is one method faster than the other?

Percussion drilling tends to be faster, especially for smaller holes, while core drilling provides a more methodical and precise drilling process.

Which method is quieter?

Core drilling is generally quieter, making it more suitable for residential areas where noise restrictions may apply.

Are there specific Auckland regulations I should be aware of for drilling?

Yes, areas like Greenlane and Grey Lynn may have restrictions on noise levels and construction times. Additionally, the Auckland Unitary Plan offers guidelines on noise and vibration, especially near sensitive locations like schools or hospitals.

How does the Auckland Unitary Plan impact my drilling project?

The Auckland Unitary Plan dictates noise and vibration levels. If you’re working close to sensitive areas, adherence to these guidelines is vital.

Which method produces more dust?

Percussion drilling can produce significant amounts of dust if done dry, whereas core drilling, a wet process, helps suppress dust.

Do I need to consult with experts before drilling large holes?

Absolutely. Drilling without proper assessment can compromise the structural integrity of a wall or building. Consulting with construction experts is essential.

How do the costs compare between core and percussion drilling?

Core drilling equipment may be costlier to rent due to its specialised nature. The precision of core drilling might also translate to longer project times and potentially higher labour costs.

Is cleanup extensive for core drilling?

Since core drilling is a wet process, it might require additional cleanup to manage the slurry or water residue.

Why is core drilling preferred for installing utilities?

For utility installations like electrical or plumbing systems, core drilling provides cleaner, larger holes, accommodating conduits and pipes efficiently.