The Science Behind Laser Cutting

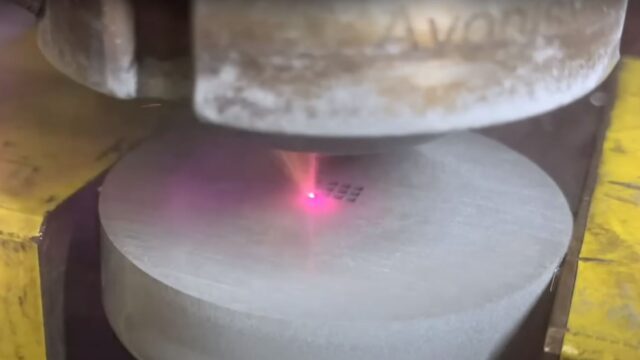

Lasers, or Light Amplification by Stimulated Emission of Radiation, are intense beams of light. When focussed on a material, their energy concentration can cause it to melt, burn, or vaporise. Commonly used in metal and plastic industries, the question arises: Is there a laser that can cut through concrete?

Current Capabilities of Lasers in Construction

While lasers are incredibly potent, cutting through concrete presents unique challenges. The thickness and composition of concrete, mixed with various aggregates and rebar, mean lasers must be incredibly powerful to make a significant impact. As of now, no commercial laser can effortlessly slice through thick concrete slabs. However, researchers are continually exploring the potential of high-powered lasers in construction applications.

Auckland’s Concrete Bylaws & Impact on Techniques

Certain bylaws in Auckland govern how and when concrete can be cut, mainly due to noise, debris, and safety concerns. In suburbs like Mount Eden and Ponsonby, there are stricter regulations due to the dense residential nature. These bylaws might limit the hours when cutting can take place and mandate specific safety and cleanup measures.

Conventional Concrete Cutting Methods

While we await advancements in laser technology for concrete, traditional methods remain predominant:

- Diamond Blade Cutting: Uses a diamond-tipped blade, providing a clean and precise cut.

- Hydrodemolition: Uses water under high pressure to remove or cut concrete, minimising dust and debris.

- Abrasive Jet Cutting: Uses a mixture of water and abrasive materials to cut through concrete.

Advantages of Potential Laser Cutting

Should lasers become a viable option for concrete, they’d offer:

- Precision: Ability to make incredibly accurate cuts.

- Reduced Noise: Potentially quieter than mechanical methods.

- Minimal Dust & Debris: As lasers vaporise material, they might produce less physical waste.

Challenges and Considerations

- Power Consumption: High-powered lasers could require significant energy.

- Heat Generation: Might result in thermal stress in the surrounding concrete.

- Safety Concerns: Direct exposure to high-powered lasers can be harmful.

Comparison of Current Techniques vs. Potential Laser Cutting

| Aspect | Traditional Methods | Potential Laser Cutting |

| Precision | High (especially with diamond blades) | Very High |

| Noise | Moderate to High | Low to Moderate |

| Dust & Debris | Moderate (Varies with method) | Low |

| Energy Consumption | Moderate | Potentially High |

| Safety Concerns | Mechanical risks (blade contact, debris) | Exposure to high-powered lasers |

The Future of Concrete Cutting

The construction world is in a state of constant evolution. With research ongoing, lasers might one day become the go-to for concrete cutting in Auckland and beyond. For now, while lasers show promise, traditional methods backed by decades of expertise remain the most reliable choice. When in need, always consult with an Auckland-based professional concrete cutter to understand the best approach for your concrete cutting requirements.

Key Takeaways: Laser Cutting and Concrete

- No commercial laser can currently slice through thick concrete slabs effortlessly, though research is ongoing.

- Traditional methods like diamond blade cutting, hydrodemolition, and abrasive jet cutting remain predominant in concrete cutting.

- Potential benefits of laser concrete cutting include high precision, reduced noise, and minimal dust & debris.

- Challenges include significant power consumption, heat generation, and safety risks with high-powered lasers.

- Auckland bylaws, especially in suburbs like Mount Eden and Ponsonby, have specific regulations regarding concrete cutting due to noise, debris, and safety.

- For reliable results, consulting with Auckland-based experts is recommended.